Waste Heat Utilization E³Tec

The estimate of the potential for heat recovery per site shows similar agreement between the two studies 0.00 0.05 0.10 0.15 Paper and Pulp Food Glass and Drinks Cement Ceramics Chemicals McKenna Low heat recovery per site Technical potential per site re-scaled to represent ETS McKenna High heat recovery per site Technical potential per site in.

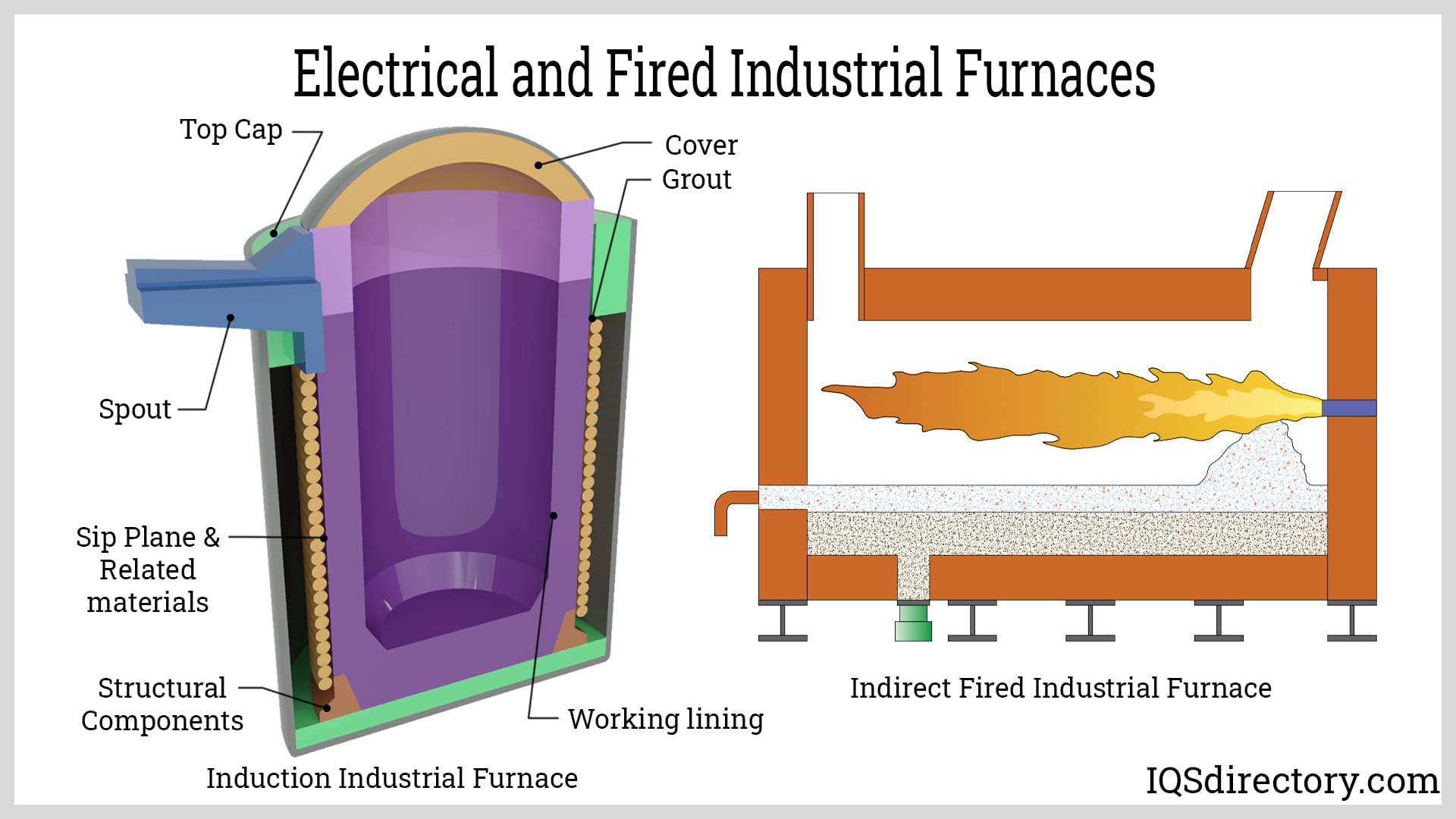

Unplugging an Electric Furnace Safety and Considerations LNG2019

D2.4 Report on barriers to the adoption of heat recovery technologies and recommendations on how to overcome them - 680599- I-THERM 3 1. Introduction The wide adoption of heat recovery technologies in industry is hindered by specific "barriers" related to both technical and non-technical issues. An attempt is made in this

(PDF) Barriers and Enablers to Recovering Surplus Heat in Industry

Objective: Explore the barriers and enablers to adoption of an Enhanced Recovery after Surgery (ERAS) program by the multidisciplinary perioperative team responsible for the care of elective colorectal surgical patients.. Background: ERAS programs include perioperative interventions that when used together have led to decreased length of stay while increasing patient recovery and satisfaction.

Why Are Heat Exchangers Used In Industry? Aggreko

Factors that affect outcomes are likely to change over time and in different contexts, and may be perceived differently by individuals, disciplines, and epistemic communities, to the extent that a barrier may become an enabler in some circumstances, and vice versa, or phenomena can be barriers and enablers.

Illustration of industry cluster case study with two source plants with

Barriers and Enablers to Recovering Surplus Heat in Industry · potential enablers that could overcome barriers and/or increase uptake of industrial heat recovery, including policy of 61 /61 Match case Limit results 1 per page

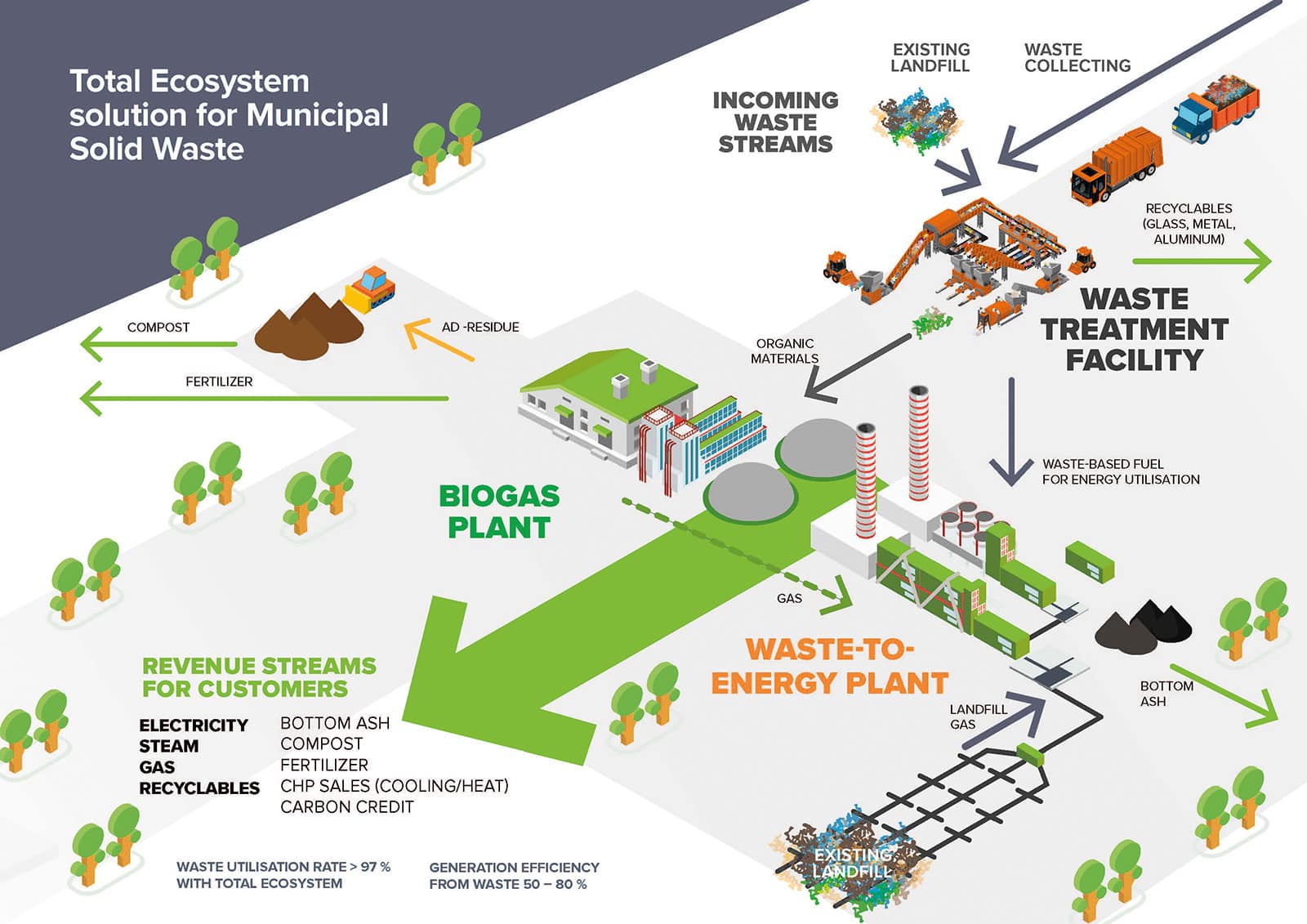

Wastetoenergy solution for municipal waste management Biovoima

Reports the findings of a study into the potential for heat recovery in seven energy intensive industries; cement, ceramics, iron and steel, glassmaking, chemicals, paper and pulp, and food and drink. Details the organisational and commercial barriers to heat recovery. Identifies enablers of heat recovery technologies. History

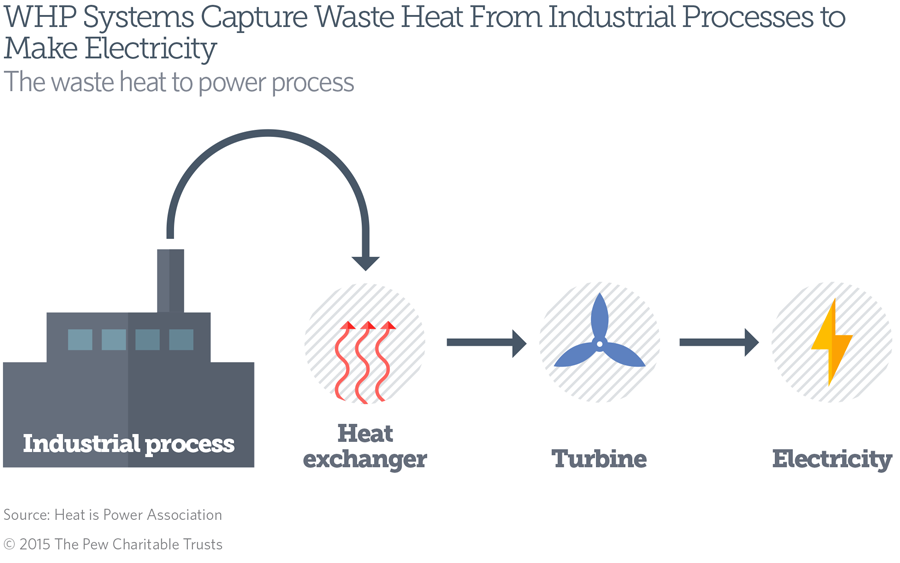

Waste Heat to Power System (WHP) for Building Facilities The Constructor

Over the past few years, Industry 4.0 has received significant global attention owning to its capability to enhance the sustainability and future competitiveness of the manufacturing sector. However, manufacturers are experiencing numerous difficulties while implementing Industry 4.0 due to the sheer number of barriers. In light of this, the present study aims to identify the Industry 4.0.

Energies Free FullText An OptimalControl Scheme for Coordinated

In most of the articles, authors referred to the barriers and enablers of using food waste from the food rescue perspective (n = 24), followed by household (n = 8), retail (n = 5), and the entire food system (n = 2). A total of 123 enablers and 104 barriers were identified 15, 17, 20, 21, 27-61.

Producing heating, cooling and surplus heating for the LTDH grid COOL DH

The top 27 drivers and 29 barriers found in the literature (including the findings of the SSA survey described in the next section of this article) are listed in. Table 1. with the full name of the author (s) of the report from which they extracted (a single letter is used to identify reports for. Table 2.

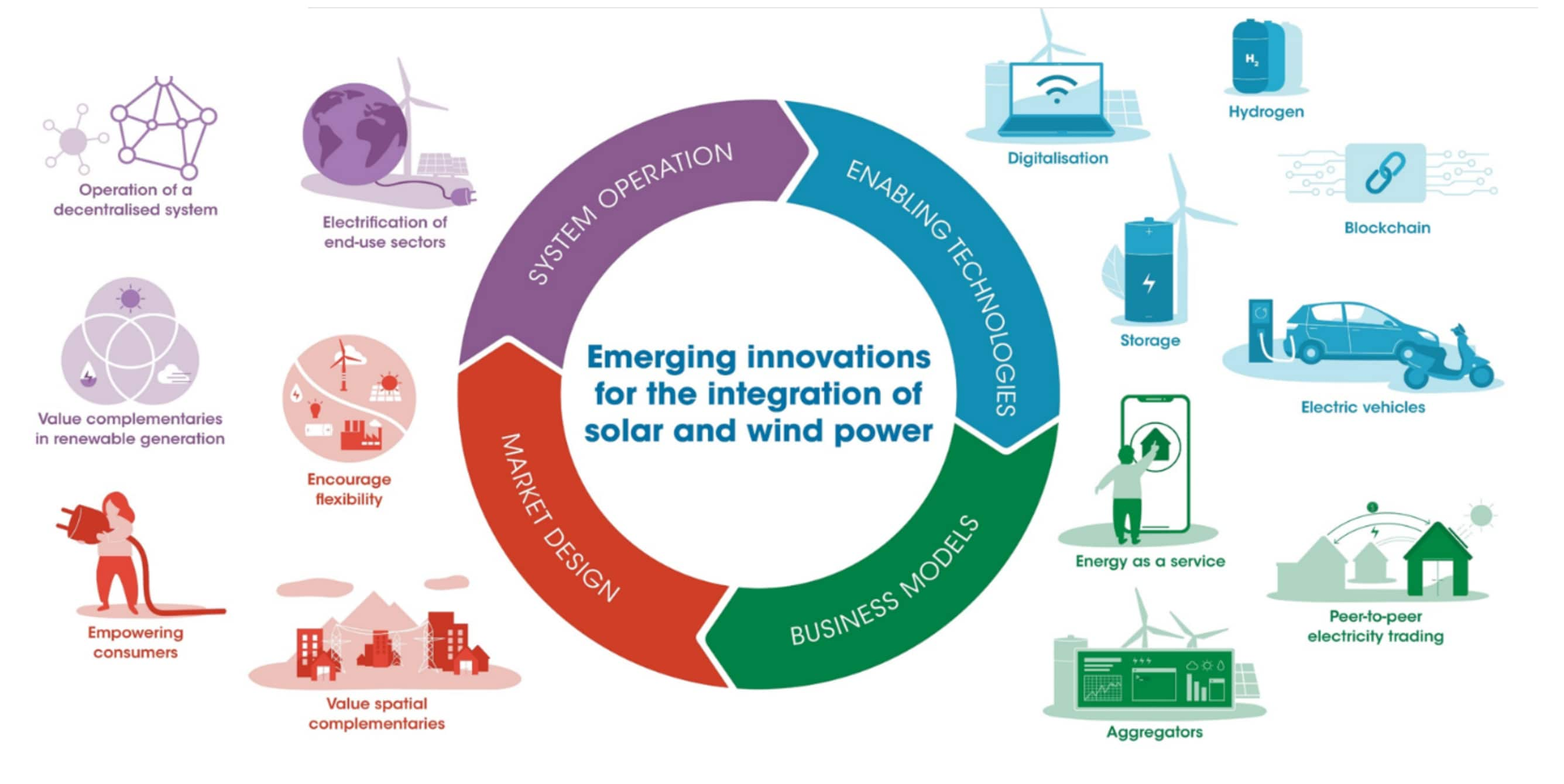

Renewable energy is the cornerstone of the energy transition World

The main barrier to waste heat recovery related to steel industries in UK are money and uncertainties. In general, the steel industries in UK have small profit margins and thereby are in the knife edge if they can keep running.. The potential for recovering and using surplus heat from industry. Department of Energy and Climate Change, London.

Mechanical Engineering Typical Waste Heat recovery System!!

Barriers and Enablers to Recovering Surplus Heat in Industry A qualitative study of the experiences of heat recovery in the UK energy intensive industries. potential enablers that could overcome barriers and/or increase uptake of industrial heat recovery, including policy implications.

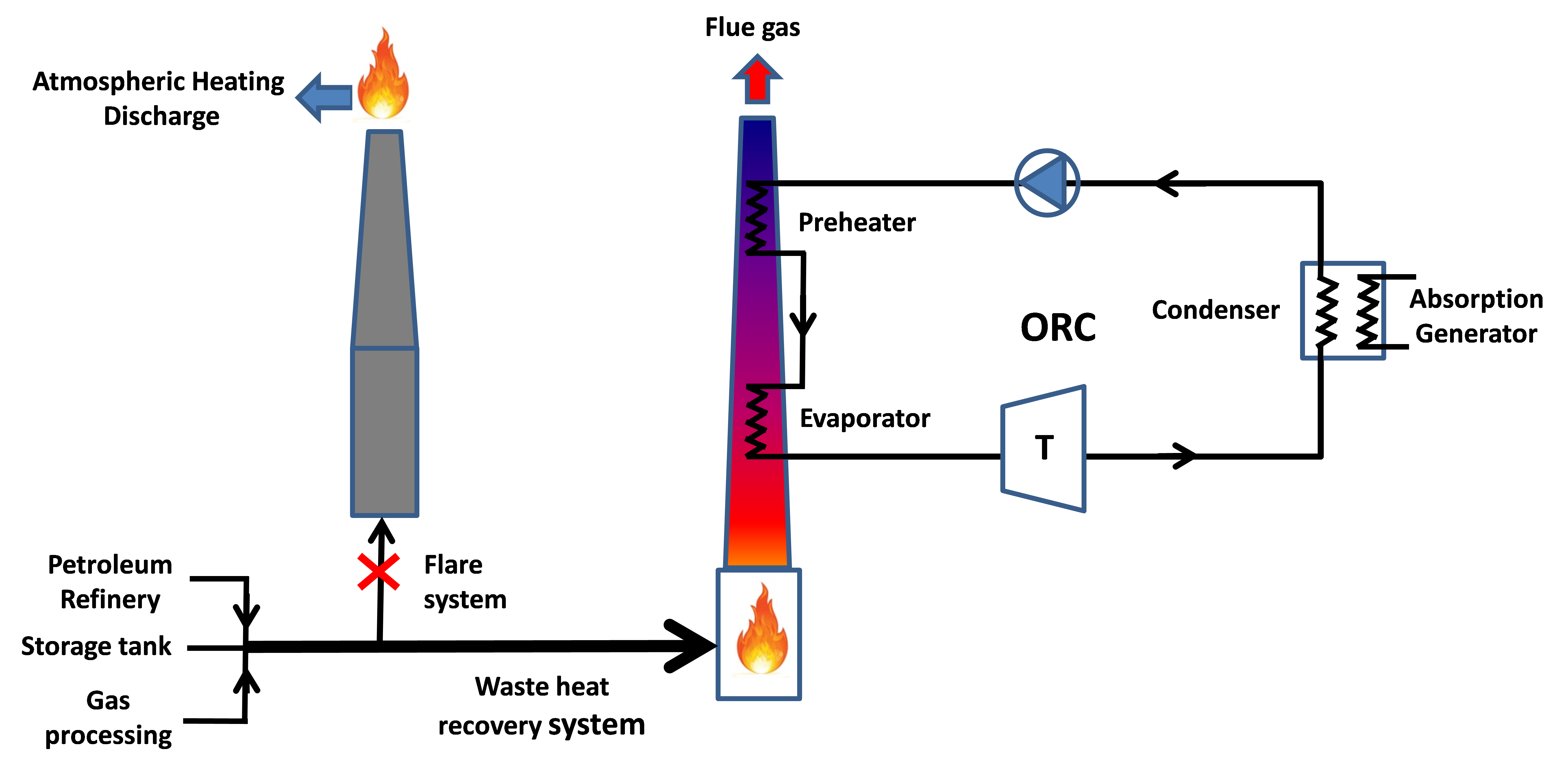

Energies Free FullText Flare Gas Waste Heat Recovery Assessment

Enablers against restoration barriers: synergistic innovations Innovation may help to overcome current barriers to restoration up- and out-scaling, applying recent developments in biophysical sciences and recovering knowledge from traditional expertise, such as re-establishing sediment laden river discharges (e.g. [83] ), which was a.

Energy Recovery from Wastewater DAS

1. Introduction - Sector Heat Recovery Potential (TWh/yr) Source: BEIS Barriers and Enablers to Recovering Surplus Heat in Industry 2016 2Source: Element Energy (Potential for recovering and using surplus heat from industry, 2014) • A BEIS study2 identified heat recovery potential of 11 TWh/yr, up to 28 TWh/yr if district heating can be utilised

Energies Free FullText An OptimalControl Scheme for Coordinated

The potential for recovering and using surplus heat from industry Final Report 3 from decisions made on the basis of this report. The views and judgements expressed here are the opinions of the authors and do not reflect those of the UK Government or any of the stakeholders consulted during the course of this project. Contact Details:

“Heat Recovery” surplus heat for local community

Barriers and Enablers to Recovering Surplus Heat in Industry: a qualitative study. 16 November 2016. The potential for recovering and using surplus heat from industry. 26 March 2014

surplusheatutilisation SINTEFblog

It is estimated Iron and Steel would recover some 17.9-35.8PJ/yr from surplus heat sources, to supply 4.5-9.0PJ/yr of electricity. In total 29-64PJ/yr of surplus heat, supplying 6.7-14.0PJ/yr of electricity, was identified for use in heat to electricity technologies. Download : Download full-size image. Fig. 10.

- Cuando Usar Adverbios Y Adjetivos En Ingles

- Efectos Nocivos Para La Salud Y El Ambiente Del Combustible

- Base De Datos De Terceros De La Comunidad De Madrid

- Complejo Troponina Tropomiosina Musuclo Esqueletico

- Api Google Maps Javascript Sensor True

- Certamen De Pintura 2016 El Estadio

- Batidos Con Frutas Para Bajar De Peso

- Subsidio Por Desempleo 6 Meses

- 200 Watt Solar Panel 24 Volt

- Tiempo Para El Puente De Diciembre 2023